6R80 Valve Body Failure – Ford Ranger

6R80 Valve Body Failure – Ford Ranger

6R80 Ford Ranger Transmission Problems: Valve Body vs. Solenoid Faults in Your Ford Ranger

If your Ford Ranger is shifting hard, slipping into limp mode, or hesitating between gears, the 6R80 automatic transmission might be crying out for attention. These symptoms are common in the PX, PX2, and PX3 Ranger models, especially those used for towing or off-road work. Many owners are shocked when they’re quoted over $6,000 for a replacement transmission second-hand unit, when the real issue is often far simpler: a failing valve body or worn solenoids.

At Brisbane Tuning & Turbo, we’ve developed a focused diagnostic and repair workflow under the Redorq Reman banner to address 6R80 faults with precision. This article walks you through the root causes of these failures, the real meaning behind common scan codes like P2700 or P2714, and how our scan and dyno process confirms the exact cause, so you can fix the issue without replacing the whole gearbox.

What Makes the 6R80 So Common (and So Problematic)?

The 6R80 is a six-speed automatic transmission built for strength. It’s based on a ZF design and built under licence by Ford, specifically for the Ranger, Everest, and similar utes. It handles plenty of torque and can survive years of towing, but like any gearbox, it has a weak link: the valve body.

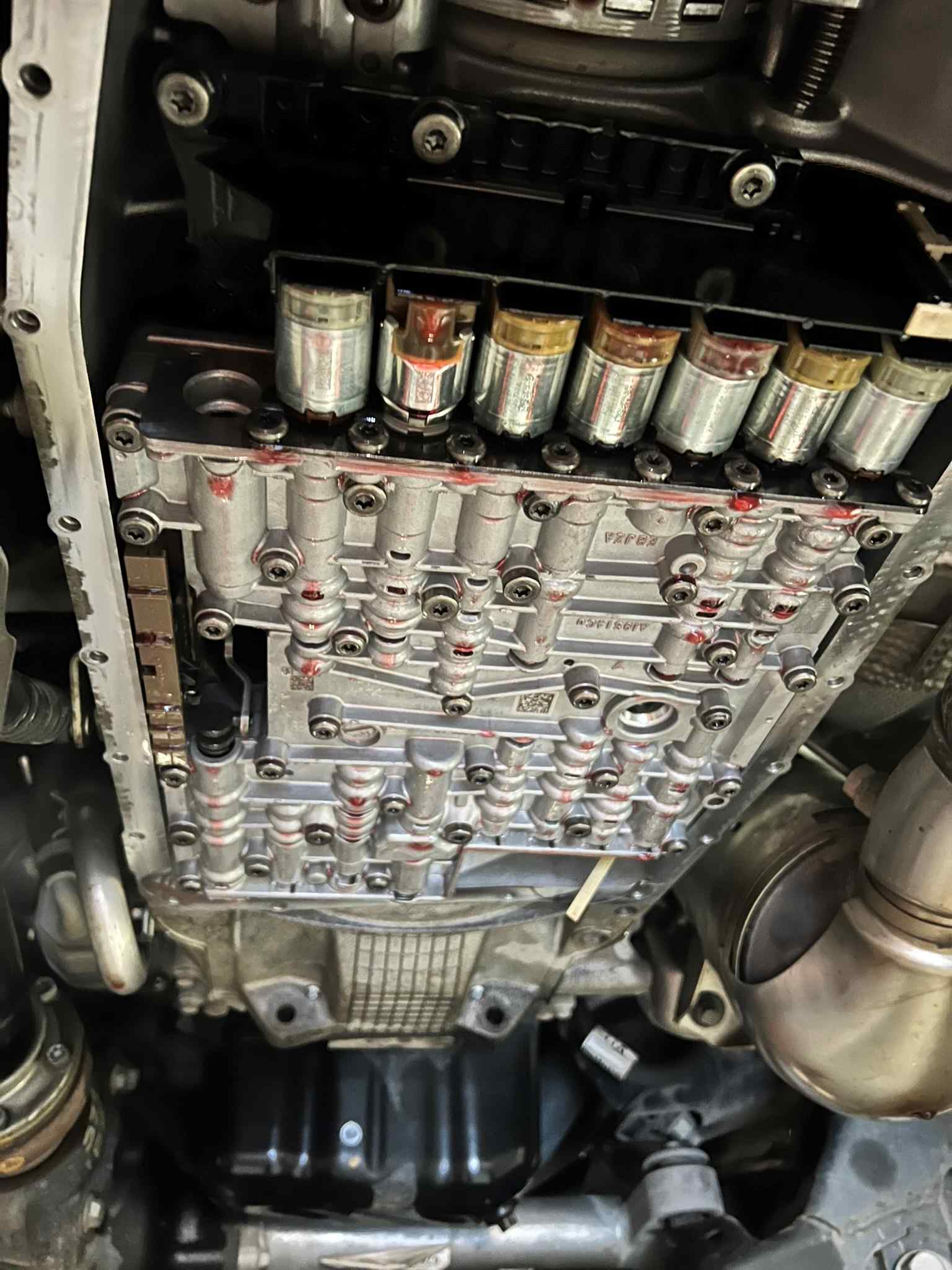

The valve body is the control centre of the transmission. It manages the hydraulic pressure needed to apply clutches, shift gears, and lock the torque converter. Over time, and especially under heat stress, the internal valve bores wear, solenoids begin to stick, and pressure regulation becomes inconsistent. This results in slipping, hard shifts, delayed engagement, or sudden limp mode.

Unlike a mechanical failure inside the gearbox, these faults can be diagnosed and repaired externally, if you know what you’re looking for and have the right tools to simulate the driving environment under load.

Scan Codes That Point to a Faulty Valve Body

When a Ranger owner brings us their vehicle after a transmission fault, we start by looking for specific trouble codes. These are stored by the Transmission Control Module and provide the first clue as to what’s going wrong inside the valve body. The most common codes we see include P2700, P2714, P0744, and P2757.

P2700

Refers to a friction element “apply time” fault. In plain terms, this means one of the internal clutches is taking too long to engage. The most likely causes include a weak solenoid, leaking pressure bore, or worn separator plate—none of which require a full gearbox replacement.

P2714

Indicates that Solenoid D is stuck off. This is especially common in the 6R80 after high-load use or fluid overheating. It often results in missing gears or rough shifts into 4th and 5th. Solenoid bore wear inside the valve body is typically the root cause.

P0744

Refers to the torque converter clutch circuit performance. Many workshops wrongly assume this means the torque converter has failed, but the more likely culprit is the pressure modulation solenoid that controls converter lock-up, which sits directly inside the valve body.

P2757

P2757 is the inverse of P0744—it tells us the converter clutch pressure solenoid is stuck on. This usually presents as shuddering under light throttle or poor cruising behaviour and is again tied to the valve body’s internal hydraulics.

All of these codes—on their own or in combination—paint a clear picture. The 6R80’s valve body is either leaking pressure internally, commanding the wrong shift timing, or allowing solenoids to drift from spec. And all of this can be confirmed before a single bolt is removed from the vehicle.

How We Use Scan Tools and Dyno to Isolate the Problem

Most mechanics will check the fault codes, quote a box swap, and move on. At Brisbane tuning & Turbo, we go several layers deeper. The “Redorq Reman” diagnostic process is structured to tell us if the fault lies in the valve body, torque converter, or the deeper internals of the transmission.

6R80 Ford Ranger Diagnostics

We begin by running a complete scan of the TCM using our diagnostic platform. We extract not just the fault codes but the freeze-frame data behind them. This shows us when the error occurred, under what load, temperature, and throttle condition. Then we pull up live solenoid data and graph it against expected behaviour. If Solenoid D is supposed to ramp up pressure in a given shift window and doesn’t—either by lagging or spiking—we see it instantly.

But scan data alone isn’t enough. We then move to the dyno. Under controlled load, we replicate the same shift conditions. We watch how quickly the clutches engage, whether torque converter lock-up occurs at the correct point, and whether flare or slip is present in the power delivery. This is especially effective for confirming issues that only occur under real load, like towing or off-road throttle events.

Once dyno and scan data confirm the behaviour and match the code profile, we perform a fluid inspection. Burnt, dark, or aerated fluid confirms overheating and pressure circuit degradation. If the clutches are still good and the transmission holds mechanical drive, it’s almost certainly the valve body.

What Actually Fails Inside the 6R80 Valve Body

When we disassemble failed 6R80 valve bodies, we often find the same patterns. The pressure regulator bore wears first. This is the main circuit responsible for line pressure regulation, and once it wears, the rest of the hydraulic timing begins to drift. Solenoids then either overcompensate or stick altogether.

In many cases, the separator plate—the steel gasket that separates the valve layers—will be deformed or warped from heat cycling. This leads to cross-leaks between circuits, erratic pressure behaviour, and inconsistent converter lock-up.

Solenoids themselves also degrade. These are electrically actuated valves that control hydraulic circuits. Over time, they begin to respond more slowly, sometimes “sticking closed” or opening when they shouldn’t. On the dyno, this appears as lag, overshoot, or delay in clutch engagement.

All of these components are serviceable as part of a valve body replacement. The transmission doesn’t need to come out. The torque converter doesn’t need to be touched. You don’t need to gamble on a second-hand unit that’s had just as hard a life.

Our Fixed-Price Repair Solution: Redorq Reman

At Brisbane Tuning & Turbo, our goal is to replace only what’s failed—and to confirm it properly before quoting. We don’t replace “good parts” with “second-hand parts” to make profit, we are in the business of repairing vehicles, and we know how to do it right. That’s why we offer a structured diagnostic and repair path for 6R80 transmission issues.

We begin with the Redorq Reman Diagnostic Assessment. This includes scan, dyno test, fluid inspection, and a full report. The fee is $285 including GST, and it gives you a clear, written answer about what’s wrong and what needs to be done next.

If the valve body is confirmed faulty, we recommend replacement with a remanufactured, bench-tested unit. These valve bodies are sourced from trusted suppliers and include all updated solenoids and hardware. The installation includes new fluid, programming, and dyno verification.

Our full replacement package starts from $1,975 including GST. This covers the remanufactured valve body, labour (5 hours), 9L of Mercon LV fluid, a new filter kit, and full reprogramming and road testing. If more time is needed for a specific vehicle we discuss it before we start.

For customers wanting extra peace of mind, we offer optional upgrades. These include a heavy-duty transmission cooler from $460 and a Redorq Remap to optimise converter lock-up and shift behaviour under load from $880.

Most 6R80 valve body jobs are completed within two business days. No guesswork, no hidden costs, and no unnecessary transmission swaps.

Ready to Book Your Diagnostic?

If your Ford Ranger is showing transmission faults or shift issues, don’t wait until it fails completely. Early diagnosis gives you more options—and a much lower bill.

Use the form below or call our team on 07 3276 7969 to book your Redorq Reman Diagnostic Package today. We’ll run the scan, simulate the fault on the dyno, and provide you with a full quote and repair path.

Redorq Reman: Accurate diagnostics. Targeted repairs. Built for working utes. Click this link if you want to read more about automatic transmission diagnostics.