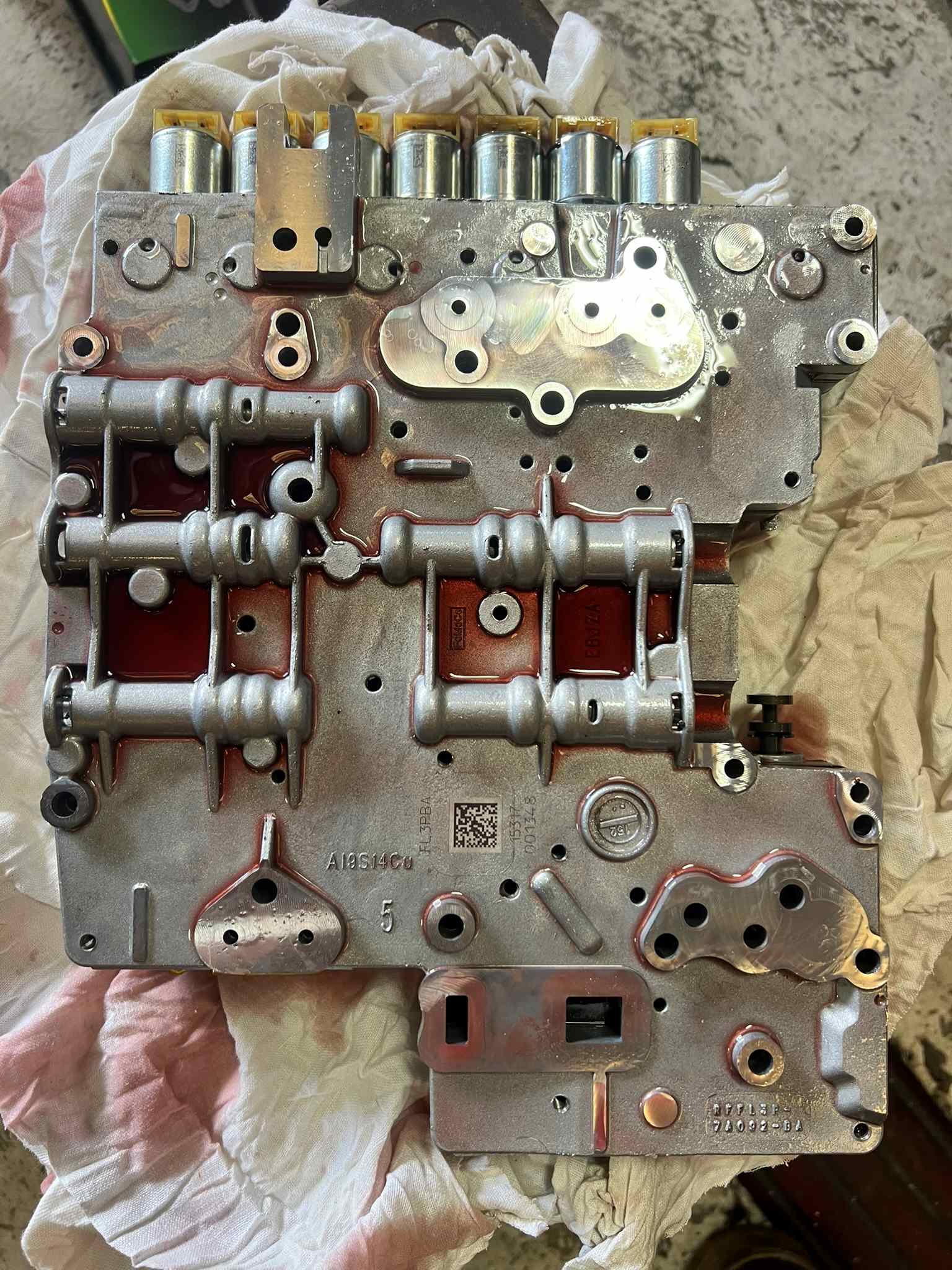

A750F Valve Body Failure

A750F Valve Body Failure

A750F Valve Body Failure – Toyota HiLux & Prado Transmission Faults Explained on 1KD-FTV and 1GR-FE.

A750F Shifting Issues: Diagnosing Valve Body Faults in Your HiLux or Prado

When your Toyota HiLux or Prado starts to shift hard, delay between gears, or randomly enters limp mode, it’s easy to assume the whole transmission is dying. Many owners go straight to a dealership and get quoted $6,000 or more for a second-hand box replacement. But in most cases, the real problem lies in one component—the A750F’s valve body. If you’re seeing this issue, don’t guess — book our Scan + Quote Only service and get a dyno-backed, scan-confirmed diagnosis before wasting thousands.

This transmission, used across a wide range of Toyota diesel and petrol platforms, is known to suffer from solenoid control issues. A750F is also known for internal hydraulic wear. Especially in vehicles that have towed, climbed, or worked hard their whole lives.

At Brisbane Tuning & Turbo, we specialise in identifying these faults with precision. Our “Redorq Reman” diagnostic process combines advanced scan tool analysis, dyno simulation, and fluid inspection to isolate the true source of the problem, so you’re not paying to replace what isn’t broken. This article explains how the A750F valve body actually fails. How it presents on common engine platforms like the 1KD-FTV and 1GR-FE, and why a remanufactured valve body is usually all it takes to restore your transmission to factory behaviour.

The A750F: A Durable Transmission With a Known Weak Point

Toyota’s A750F is a five-speed automatic transmission designed for longitudinal applications in rear-wheel-drive and four-wheel-drive vehicles. You’ll find it behind the 3.0L 1KD-FTV turbo diesel in HiLux models from 2005 through to the late 2010s, as well as the 4.0L V6 1GR-FE in Prado 120, Prado 150, and even Fortuner and Land Cruiser variants. It’s generally a solid unit, but like many electronically controlled autos from the early 2000s onward, its weak link is the hydraulic control system.

The valve body inside the A750F is responsible for directing fluid pressure to the clutches and managing solenoid operation based on input from the TCM. Over time, that control system begins to break down. Bore wear, warped separator plates, and solenoid degradation all lead to delayed clutch application, harsh upshifts, and converter lockup issues. These behaviours typically appear between 140,000 to 220,000 kilometres, right when most tradies or tourers have settled into long-term use or towing cycles.

If left unchecked, these small problems escalate. The ECU responds to out-of-spec pressure behaviour by triggering limp mode, derating torque output, and sometimes preventing gear changes altogether. The good news is that these symptoms almost never require a full rebuild if caught early, and that’s exactly where we, Brisbane Tuning & Turbo, step in. If you want to read more about automatic transmission diagnostics, click this link.

Fault Codes That Reveal Valve Body Breakdown

The most commonly reported fault in A750F-equipped HiLux and Prado vehicles is P2714.

P2714

P2714, which refers to Pressure Control Solenoid D being stuck off. This code often appears after prolonged towing or mountain driving, where heat load and continuous converter lock-up strain the hydraulic system. In most cases, the solenoid itself isn’t truly stuck—it’s fighting against a worn valve bore, a warped separator plate, or degraded fluid that can no longer transmit the correct pressure signal.

P0700

When P2714 appears, it usually brings shifting problems along with it. Delayed upshifts into third and fourth, a long flare between gears, or a hard engagement into reverse are all classic signs. Toyota’s TCM logic responds by derating gear availability or locking the vehicle in third gear, particularly when driving up inclines. The code may be accompanied by a generic P0700, which simply tells the ECM that the transmission controller is upset, without giving the driver any specifics.

P2757

Another code we frequently see is P2757, which relates to the torque converter clutch solenoid being stuck on. In real-world driving, this feels like a sudden engine bog when coasting or a shudder when cruising at steady speed. It also leads to overheating if the converter is locked when it shouldn’t be. It stresses both the fluid and the clutches inside the transmission. Just like with P2714, this code is often blamed on the torque converter. Yet more often than not, the real issue is in the valve body’s pressure control logic.

What Fails Inside the A750F Valve Body

When we pull a failed valve body from one of these Toyotas, we almost always find the same combination of problems. The first is bore wear, specifically in the solenoid control valves, where repeated heat cycling and fluid breakdown cause the aluminium housing to oval out. This leads to internal pressure bleed, delayed activation, or solenoids fighting against incorrect feedback signals.

The second failure is the separator plate. This is a thin steel gasket with machined channels that separate the upper and lower halves of the valve body. After enough time under pressure, the plate begins to warp or even crack, allowing fluid to leak between circuits. That results in incorrect pressure being applied to the clutch packs or converter clutch, which the driver experiences as a shift delay or lock-up surge.

Solenoids themselves can fail too—especially in vehicles where transmission services were skipped or fluid was never flushed. These solenoids become magnetised, sticky, or thermally unstable. They may flow too little fluid, too much, or fail to close entirely, triggering solenoid-related fault codes even when their wiring and control logic are intact.

All of these issues are identifiable through a combination of scan tool diagnostics, fluid inspection, and dyno testing. And they are all repairable without pulling the transmission.

The Redorq Reman Diagnostic Process

We’ve developed a dedicated workflow at Brisbane Tuning & Turbo to isolate A750F faults quickly and confidently. Our “Redorq Reman” process begins with a full-code scan using our diagnostic suite. We extract all current and pending DTCs, freeze-frame data, and clutch pressure sensor graphs. This lets us see when the fault occurred, under what temperature, and during which gear command.

Next, we move to the dyno. This is where our process stands apart. By loading the vehicle on our in-house dyno, we can replicate the exact driving conditions that caused the issue. We run upshift sequences, downshift under load, converter lock-up cycles, and measure real-time line pressure behaviour against TCM commands. This tells us if the problem is internal slippage, bore wear, solenoid lag, or something else entirely.

Finally, we perform a full transmission fluid inspection. If the fluid shows signs of oxidation, overheating, or metallic contamination, we log that as supporting evidence. By combining scan, dyno, and fluid results, we’re able to give the customer a full breakdown of the problem. We do it before quoting anything.

This process is offered as a fixed-price diagnostic package. For $285 including GST, the Redorq Reman Diagnostic includes scan, dyno load test, fluid check, and a written summary of the fault. There’s no guesswork, and no hidden extras.

The Repair Path: Remanufactured Valve Body Installation

If the test confirms that the valve body is the issue, we recommend replacement using a remanufactured, bench-tested unit. This includes updated solenoids, a corrected separator plate, and any known hydraulic corrections. The valve body is installed in-house, and the transmission is then topped with fresh Toyota WS fluid and dyno verified for proper operation.

Our fixed-quote repair package for A750F valve body replacement starts from $1,975, including GST. That covers the remanufactured valve body, five hours of labour, a full transmission fluid refill, programming where applicable, and post-repair dyno testing. Turnaround time is typically 2 business days, depending on parts availability.

For HiLux or Prado owners who tow or travel long distances, we also offer a heavy-duty cooler upgrade. This helps prevent future overheating. For customers with converters showing early lock-up shudder, we can include a Redorq TQ+ remap to improve torque converter control and drivability.

Why Brisbane Tuning & Turbo and Redorq Reman Is the Right Choice for Toyota Owners

Most general workshops will either quote a new transmission. Alternatively, a second-hand transmission, or take a stab at a pan-off service without the right diagnostic tools. At Brisbane Tuning & Turbo, we offer something more exacting. Our “Redorq Reman” process is built around the concept that transmission issues are not always binary. We find the exact component that failed, prove it with real data, and replace only what’s needed.

That saves your money. It saves time. And most importantly, it saves the vehicle from unnecessary surgery. For HiLux and Prado owners who rely on their vehicle for work or family travel, this means getting back on the road without compromise for much less.

Book Your Redorq Reman Diagnostic Today

If your HiLux or Prado is shifting hard, entering limp mode, or throwing solenoid fault codes, now is the time to act. The earlier you catch a valve body failure, the easier and more affordable it is to fix. Our scan + dyno diagnostic package is $285 and includes a full report, no-obligation quote, and access to our specialised Toyota repair program.

Call Brisbane Tuning & Turbo on 07 3276 7969 or book online using the form below. We’re here to get your Toyota shifting right again—without guesswork, without delay, and without replacing the entire gearbox.