What’s Actually Inside an Automatic Transmission

What’s Actually Inside an Automatic Transmission

What’s Actually Inside an Automatic Transmission – A No-BS Breakdown

Mate, it’s not just a gearbox.

For most people, an automatic transmission might as well be voodoo. It’s a sealed metal box that magically turns engine power into forward motion—until it doesn’t. Then you’re told you need a “new tranny,” no questions asked.

But here at Brisbane Tuning & Turbo, we do things differently. We actually open the box, know what’s inside, and fix just what’s busted. So this article is your no-BS breakdown of what lives inside an auto transmission, where it sits, what fails—and most importantly-when. Especially useful if you drive a Ford Ranger, HiLux, D-MAX or any Aussie ute that tows, works, or plays hard.

What Lives Inside – The Layout (Front to Back)

Let’s walk through it like you’re standing under the hoist, transmission pan off, and a coffee in hand.

What’s Actually Inside an Automatic Transmission?

1. Torque Converter – Up Front, Bolted to the Flexplate

This is your launch pad. It connects the engine to the transmission using fluid and multiplies torque. Inside you’ve got an impeller, turbine, stator, and lock-up clutch. When it fails? Usually the lock-up clutch starts slipping first—think P0741 and shuddering at cruise.

2. Front Pump – Behind the Converter

Drives the hydraulic system. No pressure = no movement. Fails when fluid is burnt or full of metal.

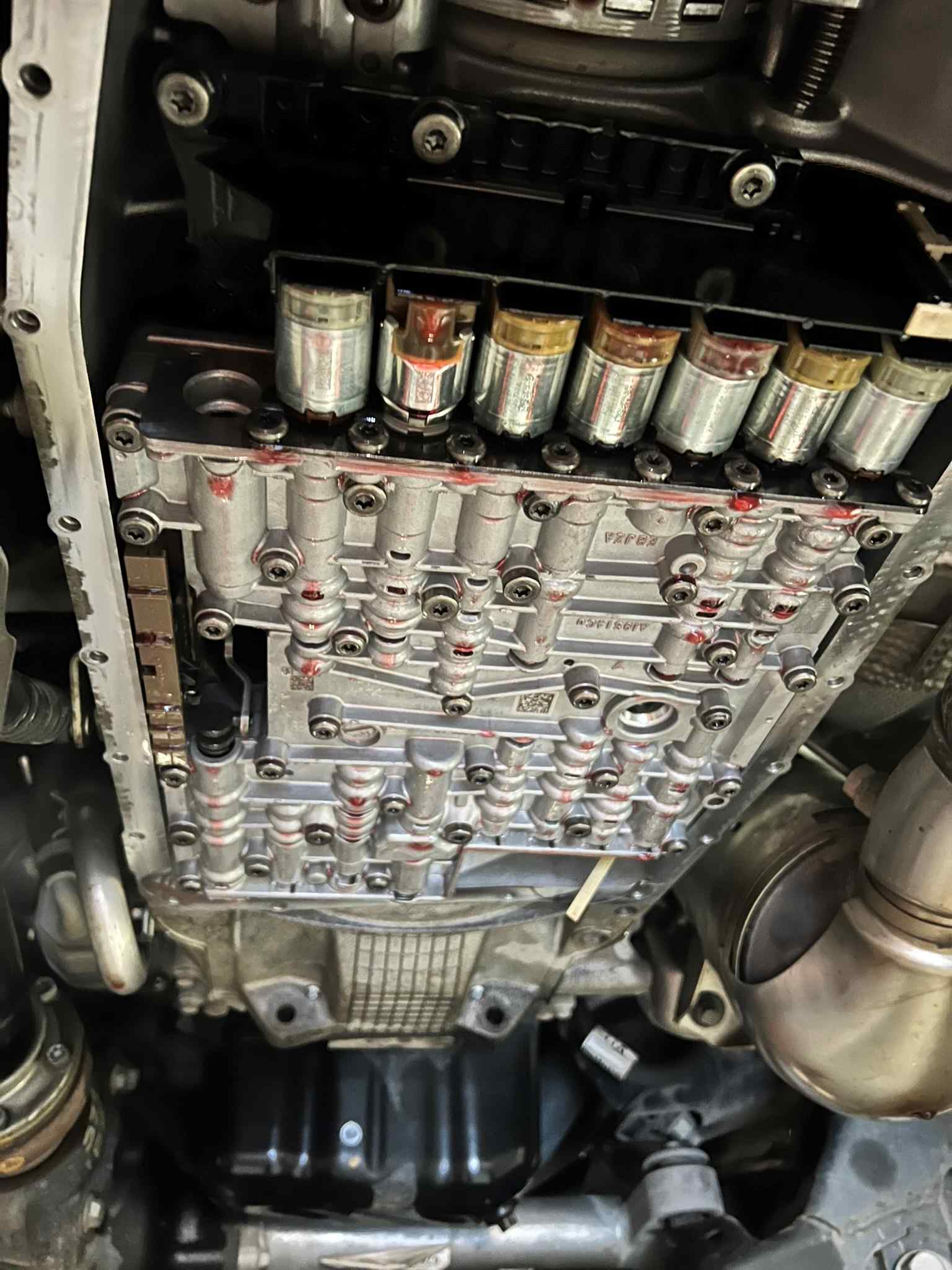

3. Valve Body – Underneath, Just Behind the Pan

This is the hydraulic brain. Directs pressure to clutches, controls gear shifts via solenoids and valves. It’s serviceable in-vehicle in many cases.

4. Clutch Packs + Drums – Deep in the Middle

Stacks of steel and friction plates. They engage different gears. They wear over time, especially if the fluid is cooked or valve body pressure is inconsistent.

5. Planetary Gearsets – The Ratio Makers

These deliver the actual gear changes. Usually reliable, but when they go—expect big bills.

6. Output Shaft + Rear Housing – The Exit Point

Connects to your tailshaft or transfer case. Vibes or clunks here can point to worn bushes or bearings.

7. Oil Pan – The Fluid Sump and First Diagnostic Window

That’s where the good (or bad) stuff collects. Metallic shimmer? Black burnt fluid? That’s your warning.

What Fails First (And What Happens If You Ignore It)

Now for the juicy bit—how things actually go wrong, and in what order.

Step 1: Heat and Fluid Breakdown

Before anything fails, the transmission gets hot. Long towing trips, traffic in summer, or just skipped servicing? That ATF starts to shear. It loses lubrication and pressure capacity. No codes yet, but you’re on the slope.

Step 2: Torque Converter Clutch Slips (P0741)

You’ll feel it cruising at 80–100km/h: the revs rise slightly, or it shudders at light throttle. That’s your converter clutch failing to lock. If it’s left unchecked, it spreads heat and metal into the rest of the box.

Step 3: Valve Body Gets Nasty (P2714, P2757, Harsh Shifts)

Separator plates wear, solenoids hang, and line pressure goes erratic. That’s where we start seeing erratic shifting, delay into reverse, or neutral drop on take-off. Catchable here—VB swap and fluid might save it.

Step 4: Clutch Packs Start to Burn

Now you’ve got internal wear. Frictions lose bite. Shifts flare or slip. Fluid goes dark or smells like burnt toast. From here, it’s game over unless you rebuild.

Step 5: Pump and Planetaries Say Goodnight

Metal travels through the system, scoring the pump. Or the planetaries start whining. No forward drive, or full hydraulic failure. This is where the “used trans” quote shows up.

Step 6: Someone Throws in a Used Box Without Fixing Root Cause

And the cycle starts again.

That’s why Brisbane Tuning & Turbo diagnoses properly before quoting. We want to stop the sequence early—not just push a time bomb down the road.

How Brisbane Tuning & Turbo Finds the Real Fault (And Why It Matters)

We don’t play pin-the-tail-on-the-fault-code. Here’s how we do it right:

1. Scan + Live Data – Check for codes like P0741, P2714, P2757. Read solenoid status. Look for slip or pressure loss.

2. Dyno Time – This is where we see real behaviour under load. Lock-up clutch issues? Line pressure drops? Shifting flare? It all shows here.

3. Fluid Check – Colour, smell, shimmer, varnish. It tells the story of what’s been cooking inside.

4. Loom Inspection (if needed) – PX Rangers and D-MAXs love to short out the harness. We check that too.

Only after this do we recommend a valve body, torque converter, or—rarely—a full transmission. It’s how we save people thousands and protect the driveline properly.

Why Diagnosis Wins Over Replacement

That $3,800 second-hand PX1 box plus install? Sounds good until it’s slipping again 6 months later. No upgraded cooler, no flushed converter, no tested valve body.

Instead, Brisbane Tuning & Turbo might solve the root cause for half that cost—new valve body, converter upgrade, and tuned shift logic. That’s what our TQ+ Packages and Redorq Reman Valve Body swaps are built for.

We don’t throw gearboxes. We fix the right part, the right way.

Need help? Book a scan + dyno appointment. Let’s see what’s really going on under there.